leachate recirculation titulo

leachate recirculation titulo

Viridian Colombia provides full integrated leachate recirculation systems, for improved leachate quality and regulation of flow during high rainfall periods. Recirculation can also improve gas quality and yield.

- Reduced leachate disposal and treatment costs.

- Significantly enhanced organic waste decomposition rates creating more landfill capacity.

- Improved leachate quality for treatment: The waste mass acts as a biological reactor thus reducing BOD and COD during the acetogenic phase. Once BOD has reduced, the leachate is then easier to treat and treatment costs are reduced.

- Buffering of peaks and troughs in COD ensuring consistent leachate quality for treatment: biological treatment plants need a reasonably consistent supply of leachate in order to function reliably; they cannot cope with “shock-loading” of strong leachate.

- There is a reduced need to store large volumes of leachate in high rainfall periods by utilising the absorptive capacity of the waste.

- Enhanced gas production in terms of both quality and volume for CDM projects.

- Accelerated settlement creating increased landfill capacity.

- Recirculation is designed to be fully integrated to leachate extraction systems.

- The recirculation pipe is inexpensive and should be regarded as sacrificial.

- Viridian leachate recirculation technology will pay for itself!

- Viridian leachate recirculation does not cause localised saturation of waste.

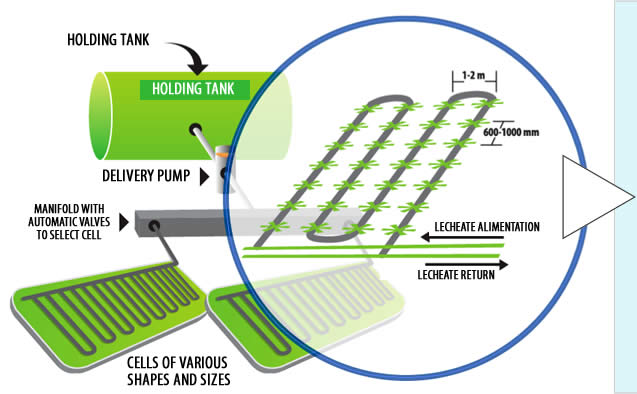

- The ACTIVE extraction system delivers leachate into a holding tank allowing some solids settling.

- Leachate is pumped from the holding tank under pressure to the recirculation system via (a) an auto-backwash filter arrangement to remove solids and organic material down to 100µm and (b) a Pipe-JetTM electromagnetic calcium carbonate scale prevention device.

- Filtered leachate is delivered to selected recirculation areas on either a timed or metered-volume control basis - this is optional and is at the discretion of the landfill operator.

- As part of the maintenance programme, the recirculation pipe system can be back-flushed to reduce silting of the emitters.

- Each pressure-compensated emitter allows dispersion of between 1 and 3.8 litres/hour.

- The dispersal pipe system is very flexible and will accommodate a high degree of waste settlement.